- Product

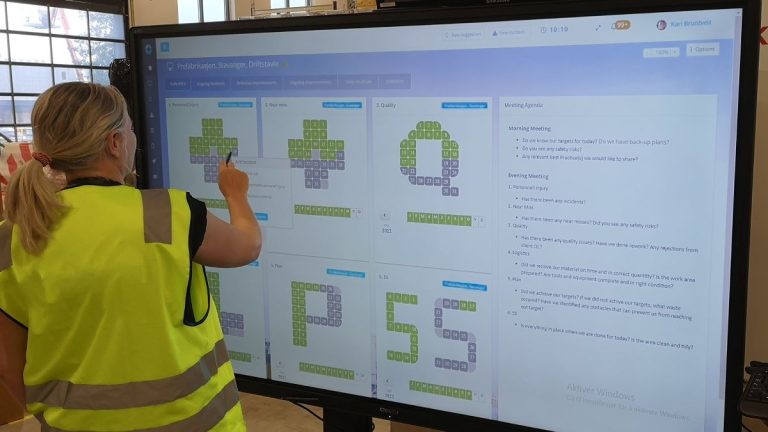

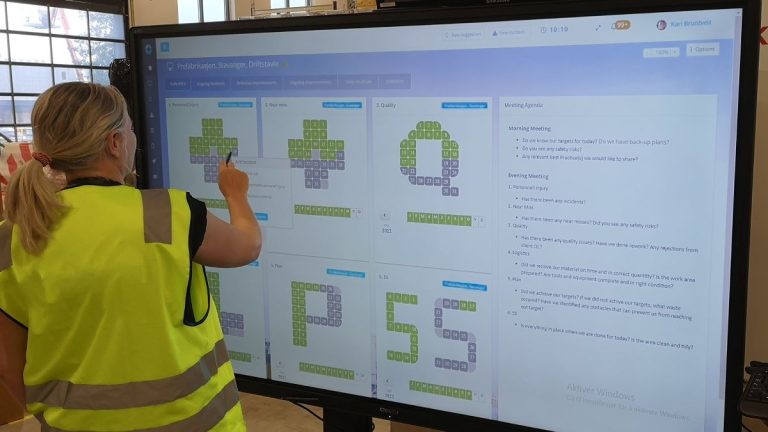

Interactive boards. Fully customizable.

Capture, prioritize and follow up improvements.

Report and manage incidents. Visualize reports and statistics.

Operationalize your strategies and integrate your whole organization.

Access your tools in Microsoft Teams.

Customized templates. Problem solving, business development etc.

Manage project individually or in portfolios with visual and interactive tools.

Create and share best practices, one-point-lectures and standards.

Easy access to tasks, improvements and incidents.

Integrate DigiLEAN with your existing IT systems.

Meeting the demand of larger organizations.

High security level by default.

In less than 4 min

- Use Cases

Interactive tools for both shop floor and administration.

Visual project management.

Maintain standards. Manage incidents and discrepancies.

Manage tasks, integrate with problem-solving and continuous improvement.

Lean daily management tailored for healthcare.

Team task management, problem-solving and visualization.Case management, improvements, problem-solving, and strategy alignment.We have a LEAN solution for you too. Just ask!

We meet the demand of larger organizations.

- Pricing

- Shop Floor

- Product

Interactive boards. Fully customizable.

Capture, prioritize and follow up improvements.

Report and manage incidents. Visualize reports and statistics.

Operationalize your strategies and integrate your whole organization.

Access your tools in Microsoft Teams.

Customized templates. Problem solving, business development etc.

Manage project individually or in portfolios with visual and interactive tools.

Create and share best practices, one-point-lectures and standards.

Easy access to tasks, improvements and incidents.

Integrate DigiLEAN with your existing IT systems.

Meeting the demand of larger organizations.

High security level by default.

In less than 4 min

- Use Cases

Interactive tools for both shop floor and administration.

Visual project management.

Maintain standards. Manage incidents and discrepancies.

Manage tasks, integrate with problem-solving and continuous improvement.

Lean daily management tailored for healthcare.

Team task management, problem-solving and visualization.Case management, improvements, problem-solving, and strategy alignment.We have a LEAN solution for you too. Just ask!

We meet the demand of larger organizations.

- Pricing

- Shop Floor

Why work LEAN?

Have you defined your goals properly?

Before we discuss why you should work with lean, let’s start discussing the foundation and success criterias for lean, or any organization for that matter.

What is an organization? A structured collection of people working together against a common goal. Typically binded by a empolyer/employee contract. But it’s all about the human resources. They are there for a reason. We have evolved far beyond the first rounds of the industrial revolutions. Even though many employees still perform repeatable work, they are capable of so much more if you trust them. This doesn’t mean that employees shall get new jobs or duties, but shall be listened to given the opportunity to voice their opinion. An organization culture that is based on trust and respect is key moving forward. Most organizations have spent a lot of time optimizing and perfecting what they do, but often forget to innovate along the way. While keeping focus on your core business, breaking out of the cycle to change and innovate may become more difficult. The innovation culture is abcent, change becomes complex and results in discouraged employees.

An innovative culture

What is LEAN?

Lean is a collection of tools and methods used to build an improvement culture in organizations. With Hoshin Kanri, you can define and secure goal achievements with horizontal and vertical alignment. Use Gemba walk to learn about the actual events in your organization. Kaizen helps you focus on and perform continuous improvement.

You are already doing it

Use Value Stream Mapping to learn and identify improvement potential in your business processes.

PDCA stands for Plan, Do, Check, Act and is a method for constantly measure your improvement, set a higher standard and move forward – Continuous Improvement.

The five principles of lean

Team meetings, daily hustle, morning meeting, standup meetings are key elements of practicing lean. These are typically short, limited to the daily activities and based on open dislogue between the team members.

– How did it go yesterday?

– Plan for today?

– Any blockages or issues that requires assistance?

Advantages

When implementing and practicitng lean, your organization become more agile and suited to adapt to changes in your surroundings. With less stress and effort, your organization can adapt to new demands and challenges in the market.

At the same time, lean lets your improve performance, help you define ways to solve problems and measure results. Incremental improvement reduces the risk and innovation becomes a natural part of the companys mindset.

Key sucess factors

- Management commitment

- Employee engagement

- Competence

- Measure performance

- Celebrate success

Typical pitfalls

- Believing lean will fix everything by itself

- Passive leadership

- Lack of available tools

- Conflicting metrics

- Conflict of interest – bad culture

Talk to us today. Let's discuss your situation and see how DigiLEAN can help your business.

© 2025 DigiLEAN AS