- Product

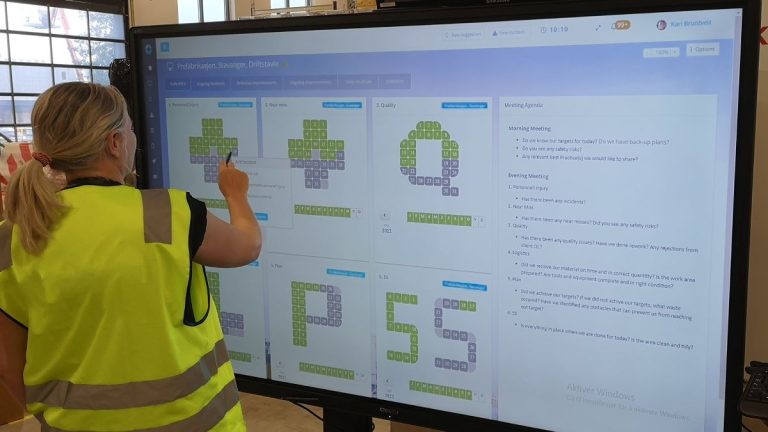

Interactive boards. Fully customizable.

Capture, prioritize and follow up improvements.

Report and manage incidents. Visualize reports and statistics.

Operationalize your strategies and integrate your whole organization.

Access your tools in Microsoft Teams.

Customized templates. Problem solving, business development etc.

Manage project individually or in portfolios with visual and interactive tools.

Create and share best practices, one-point-lectures and standards.

Easy access to tasks, improvements and incidents.

Integrate DigiLEAN with your existing IT systems.

Meeting the demand of larger organizations.

High security level by default.

In less than 4 min

- Use Cases

Interactive tools for both shop floor and administration.

Visual project management.

Maintain standards. Manage incidents and discrepancies.

Manage tasks, integrate with problem-solving and continuous improvement.

Lean daily management tailored for healthcare.

Team task management, problem-solving and visualization.Case management, improvements, problem-solving, and strategy alignment.We have a LEAN solution for you too. Just ask!

We meet the demand of larger organizations.

- Pricing

- Shop Floor

- Product

Interactive boards. Fully customizable.

Capture, prioritize and follow up improvements.

Report and manage incidents. Visualize reports and statistics.

Operationalize your strategies and integrate your whole organization.

Access your tools in Microsoft Teams.

Customized templates. Problem solving, business development etc.

Manage project individually or in portfolios with visual and interactive tools.

Create and share best practices, one-point-lectures and standards.

Easy access to tasks, improvements and incidents.

Integrate DigiLEAN with your existing IT systems.

Meeting the demand of larger organizations.

High security level by default.

In less than 4 min

- Use Cases

Interactive tools for both shop floor and administration.

Visual project management.

Maintain standards. Manage incidents and discrepancies.

Manage tasks, integrate with problem-solving and continuous improvement.

Lean daily management tailored for healthcare.

Team task management, problem-solving and visualization.Case management, improvements, problem-solving, and strategy alignment.We have a LEAN solution for you too. Just ask!

We meet the demand of larger organizations.

- Pricing

- Shop Floor

5S – You are already doing it!

For many, using 5S is a natural method of introducing lean. The threshold is low, and the results comes instantly. However, it is very common that organizations want to build a lean culture before introducing tools and methodologies, and this is actually where many fails.

Failure can be defined in many ways. Perhaps the goal and vision for the culture was set wrong. Perhaps the organization culture was already prepared to introduce lean?

Howcome?

Many aspects of lean and 5S is based on common sense. Basically, we are adding a language to what everyone is thinking – in this case Japanese terminology.

5S meaning

Seiri

Sorting

Remove items not relevant for the work or location.

Reduce time looking for items.

Reduce distraction due to mess.

Optimize use of space.

Seiton

Set in order, straighten

Create an optimal workflow by placing items where they are applicable. Keep tools and appliances near the task at hand.

Seiso

Shine

Keep your workplace clean and tidy. Inspect and shine regularly to keep a pleasing workplace. Defects are detected more easily; waste and errors are reduced.

Seiketsu

Standardize

Ensure repetition of the first three S’s. This is where the practice is established, supported by processes and procedures.

Shitsuke

Sustain self-discipline

When the practice is established, a culture is developed where people are self-motivated to continue and improve the new practice. The employees have taken ownership of the process.

Human psychology

Adding definitions and a language to intangible knowledge helps us focusing on the right things. It helps us communicate and thus improve and develop together.

Mental coaches and various studies tell the same story about how we can be more satisfied in our personal life. The facets are pretty much the same as in lean 5S. Take this article from Forbes as an example: “Ten Hacks For Simplifying Your Life”.

- The two first points are about getting rid of unnecessary stuff (and people). This resembles the first S.

- The next is meal planning. This is the second S – keeping things available when needed, where needed.

- Fourth item “Create a morning ritual” is represents the fourth S – standardize with a certain process.

- And so on…

Categorizing people is an easy and efficient way of simplifying the world and reducing mental effort.

The book “Social Psychology and Human Nature” (R.F. Baumeister PhD, B.J. Bushman PH.D, 1980) elaborates on relations between people. There are many effects of human psychology in play here, and they can relate to lean. We use social categorization every day without thinking about it. A big difference between sorting people and objects is the level of emotional involvement. Despite this, sorting people is easy, but sorting items at your workplace often seems difficult. It is all about structure, practice and making a change – of course supported by the company’s management.

Practice only fails if you stop trying. If you keep failing, you need to change your approach.

I do believe that we are all practicing 5S to some extent every day without using the definitions, and not sharing these thoughts with others. Except when calling it common sense. Perhaps our own mental barriers are preventing success. If we break down the walls, we can invite success.

If you want to know more or would like an online demonstration of DigiLEAN, please contact us!

© 2025 DigiLEAN AS