- Product

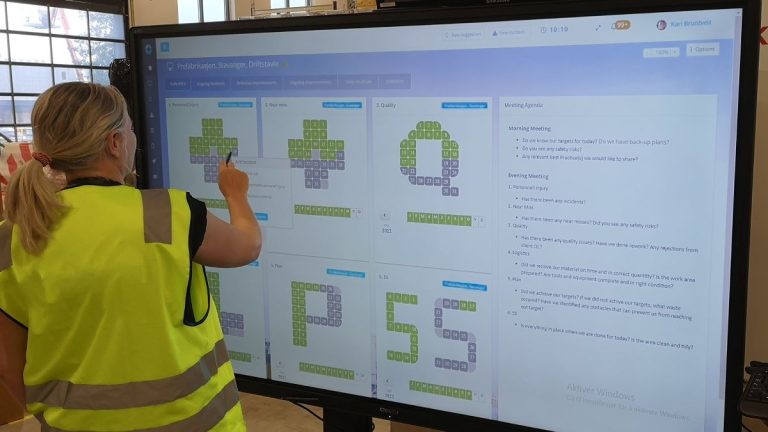

Interactive boards. Fully customizable.

Capture, prioritize and follow up improvements.

Report and manage incidents. Visualize reports and statistics.

Operationalize your strategies and integrate your whole organization.

Access your tools in Microsoft Teams.

Customized templates. Problem solving, business development etc.

Manage project individually or in portfolios with visual and interactive tools.

Create and share best practices, one-point-lectures and standards.

Easy access to tasks, improvements and incidents.

Integrate DigiLEAN with your existing IT systems.

Meeting the demand of larger organizations.

High security level by default.

In less than 4 min

- Use Cases

Interactive tools for both shop floor and administration.

Visual project management.

Maintain standards. Manage incidents and discrepancies.

Manage tasks, integrate with problem-solving and continuous improvement.

Lean daily management tailored for healthcare.

Team task management, problem-solving and visualization.Case management, improvements, problem-solving, and strategy alignment.We have a LEAN solution for you too. Just ask!

We meet the demand of larger organizations.

- Pricing

- Shop Floor

- Product

Interactive boards. Fully customizable.

Capture, prioritize and follow up improvements.

Report and manage incidents. Visualize reports and statistics.

Operationalize your strategies and integrate your whole organization.

Access your tools in Microsoft Teams.

Customized templates. Problem solving, business development etc.

Manage project individually or in portfolios with visual and interactive tools.

Create and share best practices, one-point-lectures and standards.

Easy access to tasks, improvements and incidents.

Integrate DigiLEAN with your existing IT systems.

Meeting the demand of larger organizations.

High security level by default.

In less than 4 min

- Use Cases

Interactive tools for both shop floor and administration.

Visual project management.

Maintain standards. Manage incidents and discrepancies.

Manage tasks, integrate with problem-solving and continuous improvement.

Lean daily management tailored for healthcare.

Team task management, problem-solving and visualization.Case management, improvements, problem-solving, and strategy alignment.We have a LEAN solution for you too. Just ask!

We meet the demand of larger organizations.

- Pricing

- Shop Floor

5 Principles of LEAN

Identify value

What is value?

It depends on whom you ask. Your focus shall always be with our customers. How you create value for your customer differs from what you do, and who your clients are.

Ask yourself:

- Who are my customers?

- Why do they need our products?

- How does our product help the customers?

Any sustaining business must provide:

- Products that meets your customer’s needs.

- Products without unnecessary features.

Why?

Devote your energy to product attributes customers are willing to pay for and eliminate wasteful features your market isn’t interested in. You must create a product needed by your customers, and you have to differentiate yourself from your competitors to make customers buy your product instead of others.

Value Stream Mapping

Value stream mapping (VSM) is a tool to describe and visualize your company value stream. Perhaps it’s not a tangible tool, but more of a method. Nevertheless, it is used to identify waste, bottlenecks and improvement areas.

Value streams are often large and complex, thus mapping it on a visual board takes a lot of space and often requires multiple participants to include all aspects.

Get an overview of the current situation:

- Plan your VSM scope

- Put together a diversified collaboration team representing the company’s vertical axis.

- Define the core business process

- Break down the core business to sub-processes

- Draw and visualize the processes

Identify and discuss bottlenecks, pain points and improvement areas. This will create the foundation to design the future state of the value stream.

The outcome should be a set of SMART targets for your organization, all of which to drive the processes towards a common goal: Improvement.

Different initiatives and actions require different tools. At this stage some will be run as projects, some can be solved using an A3

Flow

Making changes in your organization according to the value stream mapping may cause disruptions in your flow. The general process of any change is:

- Identify problem

- Break down

- Rebuild

- Stabilize

At this stage, re-creating and optimizing flow is part 4 of the change process.

The organization needs practice to optimize new flows, new procedures, new dependencies, new paths etc. Management is key to measure, analyze, correct, and support the employees in this phase. A new organizational culture may also be needed. Cross divisional collaboration is more efficient than traditional silo-thinking. Therefore, top level management engagement is also important to succeed.

Pull

What is pull? There are typically two perspectives on the pull principle. Most typically is the Just -In-Time (JIT) technology often referred to as JIT manufacturing. This means to product your product only when needed. It requires streamlined supply chains and results in reduced inventory and reduced part in production.

Pull in office environments are generally described differently, but the principle of doing only what is required of you is essentially the same. For example, develop a product or a service for customers based on customers requirements. This can be used for made-to-order (MTO) and engineered-to-order (ETO) products also. Even if you have a standardized product, you can use the pull principle to get valuable input from the market to create the most valuable product and avoid waste.

It doesn’t mean you are free of responsibility. It doesn’t mean you should do everything a client asks for. You still need to be true to your strategies, but customers can help decide how you create value and when. This philosophy could also create a better customer relationship. Customers are people. People are driven by motivation and this business model gives your clients respect, recognition and freedom to influence your product.

Seek perfection

As a product owner or a business manager it’s often difficult to navigate with various inputs dragging you in different directions. We are not only talking about one product, but one or many product portfolios or product ranges. The level of control required to succeed is extreme, and no one gets it right the first time. That’s why the most important thing is to have the build a solid foundation, have a clear path in terms of vision and strategy, and continuously improve, seeking perfection.

Continuous improvements are often run by the PDCA method. PDCA stands for plan, do, check, act.

Plan – define your problem and identify the root cause.

Do – Develop a solution and implement.

Check – Measure the success of your solutions.

Act – Document results, set a new standard, share experiences and repeat.

A solid foundation may force you to think new, think alternatively. It may require changing the most difficult thing in the world, the company culture. Continuous improvement (Kaizen) is synonymous with constant change. So, the company culture must support constant changes. Normally organizations resist change. But if you can involve all your employees in the process, you can build a culture for change. The upside of Kaizen is that doing improvements continuously, every incremental improvement seems smaller than the typical revolutionary change that comes from years of procrastinating or postponing decisions.

Lastly, give your employees the tools to participate and act. Keep in mind that knowledge is a powerful tool. It doesn’t help giving someone a nice and shiny tool if they don’t know how and when to utilize it. However, once the knowledge and perspective are in place, the possibilities and potential are endless – if you allow it to be.

If you want to know more or would like an online demonstration of DigiLEAN, please contact us!

© 2025 DigiLEAN AS