Daily management boards are at the heart of effective plant-floor operations. They give teams a clear view of performance, help leaders spot issues early, and create a culture of accountability and continuous improvement. But the true power of these boards depends on the KPIs you choose to track – and how consistently you act on them.

In this article, we break down the most important KPIs for manufacturing teams, how to organize them on a daily management board, and what good KPI practice looks like in Lean-driven operations.

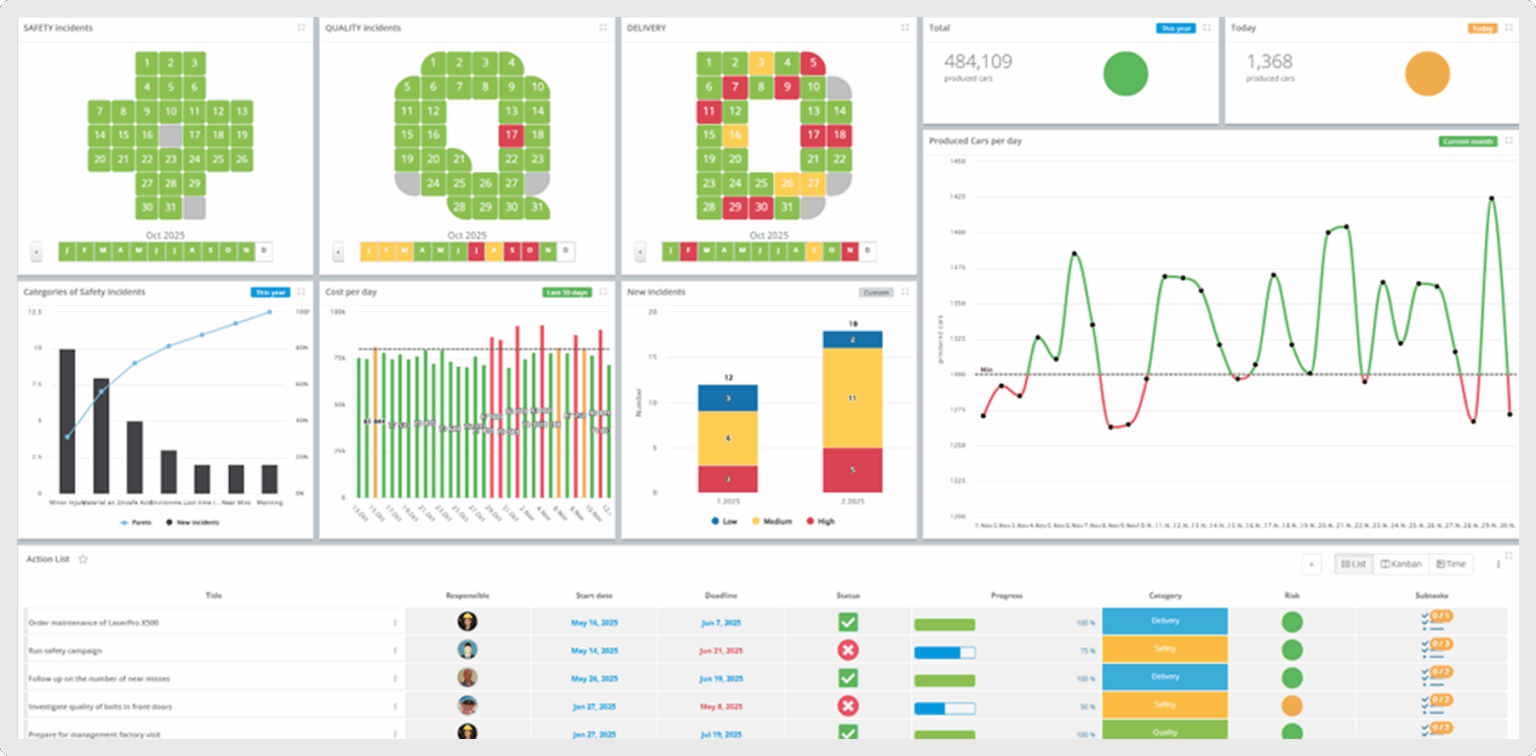

In manufacturing, KPIs are meant to support daily execution, not reporting after the fact. A digital daily management board in DigiLEAN turns KPIs into a practical, shared view of how the operation is performing today.

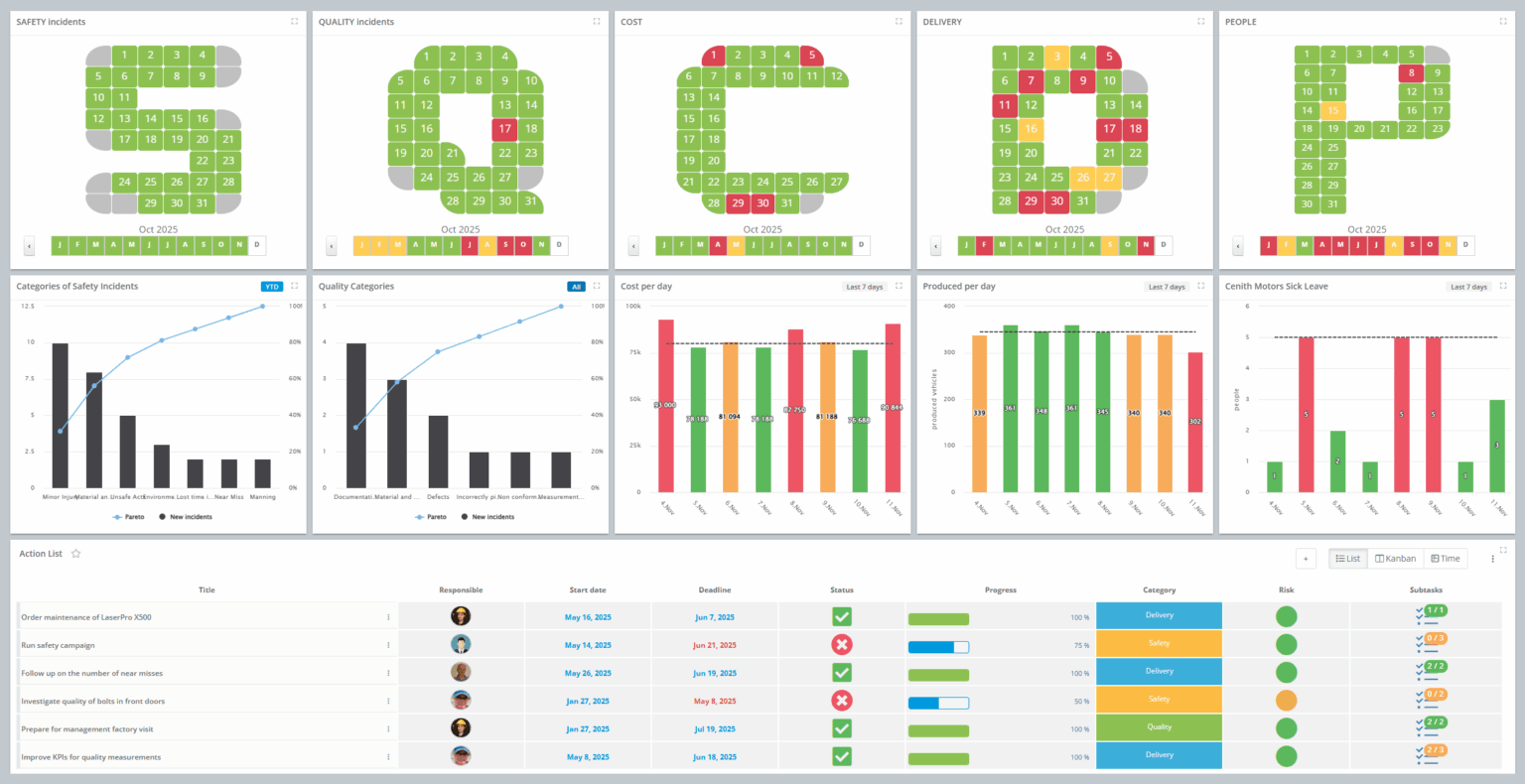

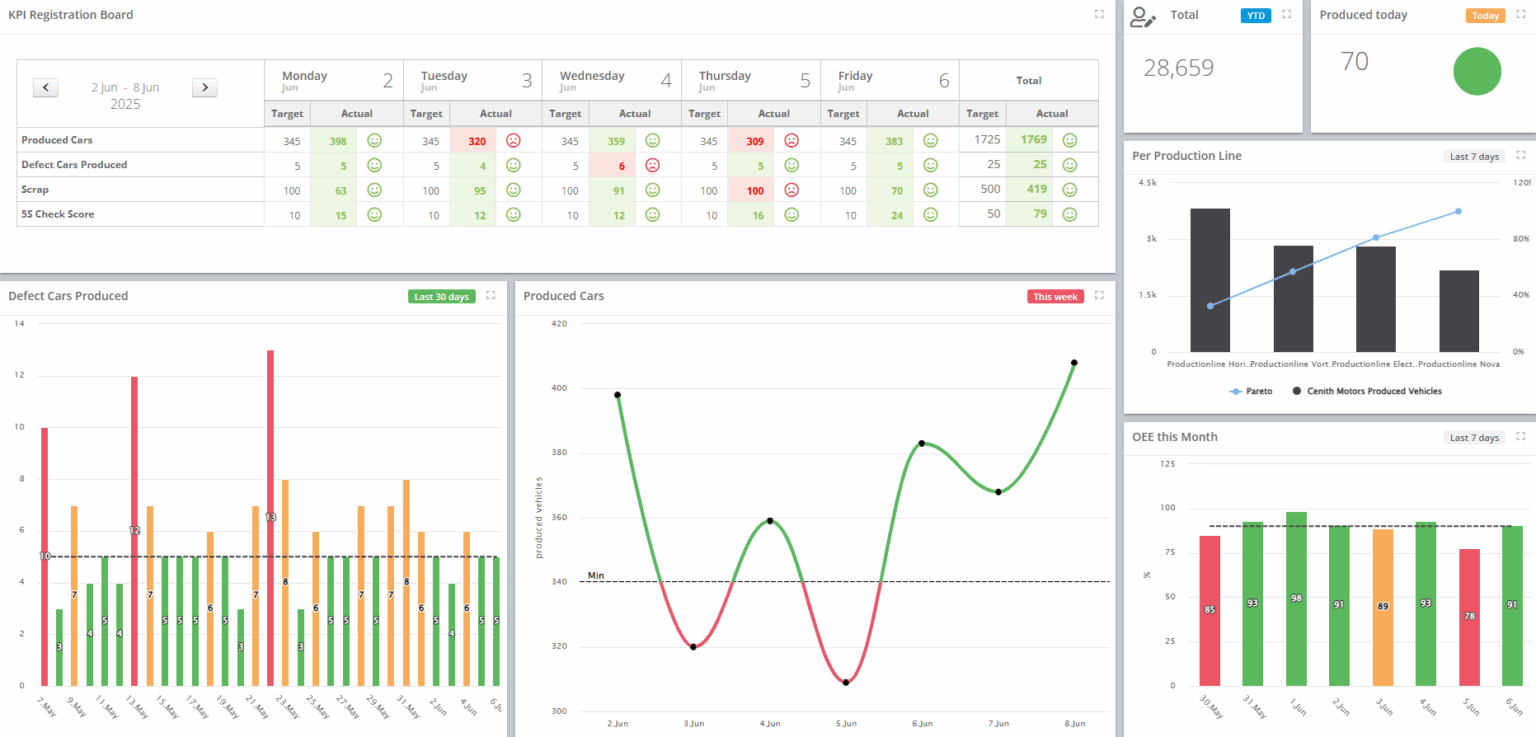

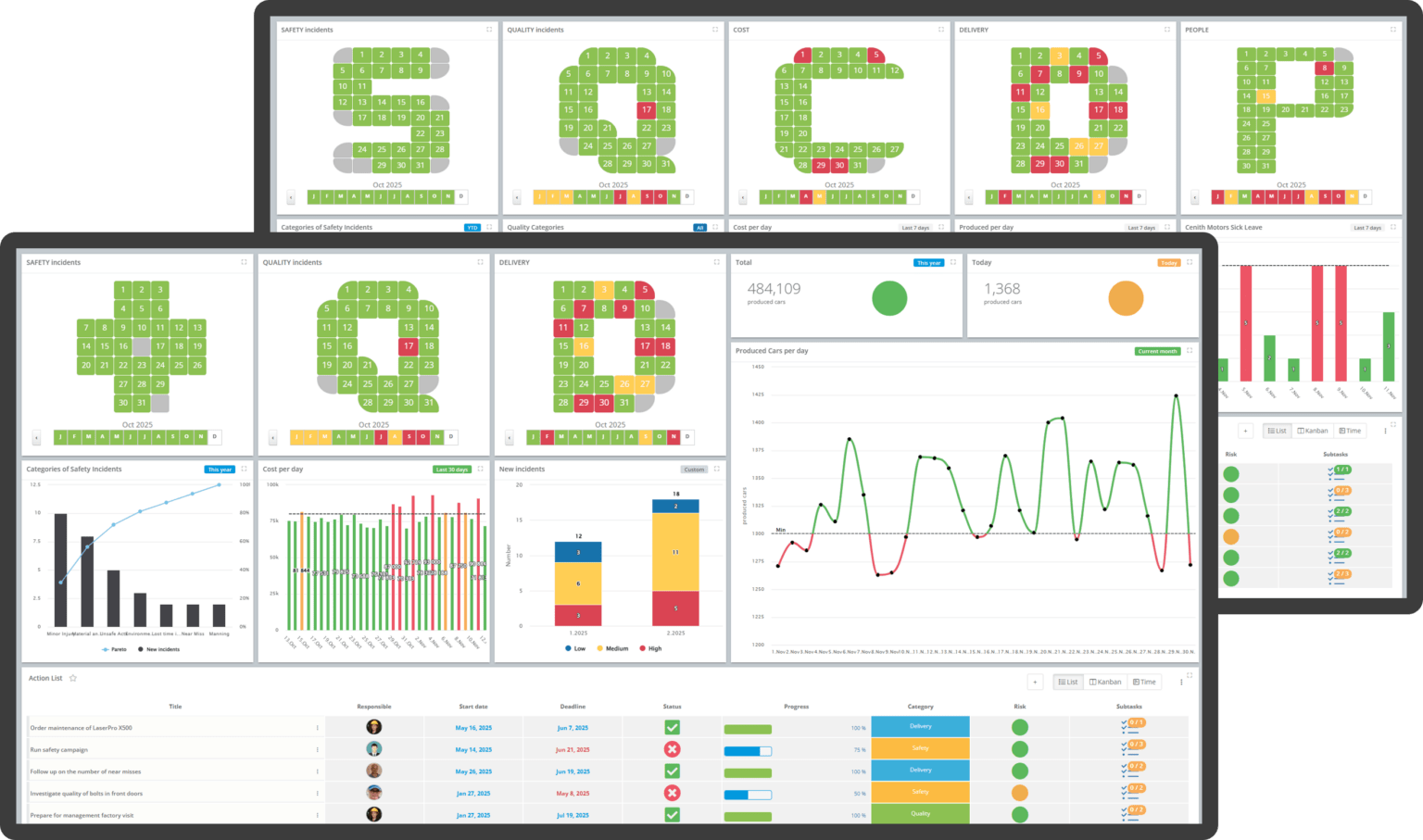

On a DigiLEAN board, KPIs are visualized day by day with clear status colors. At a glance, teams can see where performance is on track and where attention is needed. Instead of reviewing weekly spreadsheets, deviations are visible during daily meetings-when teams still have the ability to react.

When a KPI shows a deviation, it naturally becomes a discussion point. Teams focus on what changed, what risk it creates, and what action is required. Repeated deviations stand out over time, helping teams identify patterns rather than isolated incidents.

The board also supports follow-up by connecting KPI deviations to concrete actions. Tasks are assigned with owners, deadlines, and visible progress, ensuring that issues are not only discussed but actively addressed.

Because the same KPIs are reviewed every day in one shared board, accountability improves across shifts and roles. Over time, this consistent way of working strengthens daily management routines and supports continuous improvement.

In practice, this is what KPIs in manufacturing are meant to do:

Many manufacturing plants structure their daily KPIs around the traditional SQCDP framework, providing a clear and consistent foundation for daily performance management.

SQCDP captures core operational priorities, but modern manufacturing environments often need visibility beyond these five pillars. Today, high-performing teams expand their KPI structure to include:

This multi-column approach gives leaders a holistic view of plant performance and supports better cross-functional communication.

Visual status indicators make it clear where attention is required, allowing daily meetings to focus on problem areas rather than reporting.

In the example below, selected KPIs are tracked daily on a DigiLEAN board, showing produced units, defect counts, and cost-related measures and clearly highlighting which KPIs are within limits, and which require attention.

A well-structured manufacturing KPI dashboard makes performance instantly clear. A typical layout may include:

S | Q | C | D | P | Financial | Customer | Operational | Project

Strong boards share a few characteristics:

DigiLEAN’s interactive boards make this easier with automatic updates, live KPI views, and structured follow-up processes.

Choosing the right KPIs helps teams focus daily discussions on what truly affects performance. The examples below reflect common manufacturing KPIs that support effective daily management when reviewed consistently.

Here are practical daily KPIs you might track on your board:

| KPI Category | Example KPIs | Typical Review Frequency | Typical Owner |

|---|---|---|---|

| Safety (S) |

Near misses Recordable incidents Safety audits completed |

Daily | Team leader / Supervisor |

| Quality (Q) |

Defect rate First-pass yield Customer returns related to quality |

Daily | Team leader / Quality lead |

| Cost (C) |

Cost per unit Scrap cost Overtime cost |

Daily / Weekly | Supervisor / Operations manager |

| Delivery (D) |

On-time delivery (OTD) Schedule adherence Backlog |

Daily | Team leader / Planner |

| People / Productivity (P) |

Attendance Training completed Productivity vs. target |

Daily | Team leader |

| Financial |

Daily revenue vs. target Cost per unit |

Weekly / Monthly | Operations manager / Plant manager |

| Customer |

CSAT (customer satisfaction) OTIF (on-time, in-full) Complaints, return/defect rate |

Weekly / Monthly | Operations manager / Customer quality |

| Operational |

OEE (availability, performance, quality) Unplanned downtime Cycle time vs. standard Inventory turns |

Daily | Team leader / Maintenance |

| Project |

% completion vs. plan Milestone status (R/A/G) Budget utilization Identified risks |

Weekly | Project owner / Manager |

Ultimately, effective manufacturing KPIs are defined by their quality, not their quantity. A small set of well-chosen, actionable KPIs reviewed daily will always create more value than a long list of metrics that do not drive decisions. When KPIs clearly signal where action is needed and lead to follow-up, they become a practical management tool that supports accountability, problem-solving, and continuous improvement across all levels of the organization.

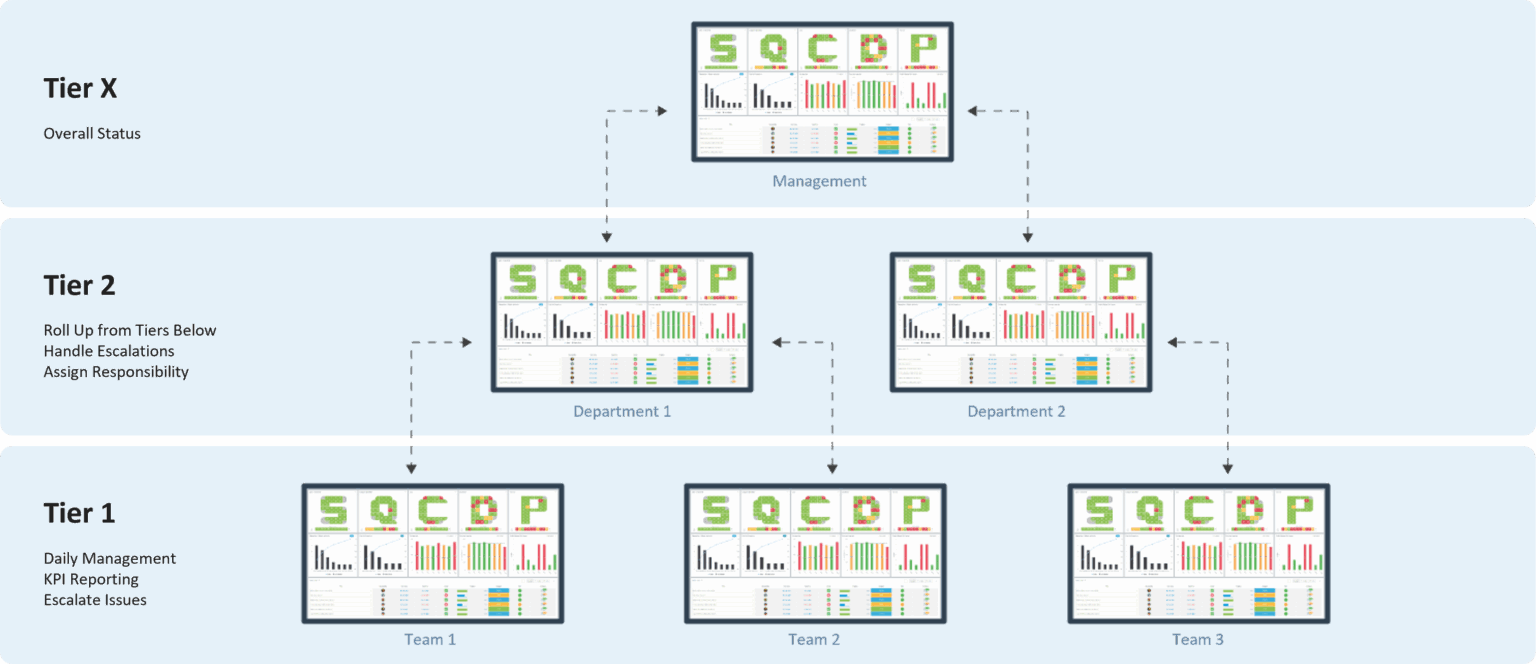

A high-performing daily management board does not stand alone – it connects into a structured tiered meeting system. DigiLEAN daily management boards are linked across tiers to ensure alignment from team level to management level.

| Tier | Focus of KPI Review | Typical Outcomes |

|---|---|---|

| Tier 1 – Team level | Review daily KPIs, identify deviations, and address issues that can be solved within the team. | Local actions agreed, owners assigned, unresolved issues escalated. |

| Tier 2 – Department level | Review KPI status and escalated issues from multiple teams to identify cross-team or resource-related problems. | Cross-team actions assigned, priorities aligned, support provided to teams. |

| Management tier | Review overall KPI status, trends, and recurring escalations that require management decisions. | Decisions made on priorities, resources, and follow-up across the organization. |

Because all tier boards in DigiLEAN are connected, updates made at one level are reflected across the system. This eliminates manual reporting, ensures consistency between tiers, and keeps tiered meetings focused on decisions and follow-up rather than data preparation.

When tiered KPI reviews are supported by synchronized DigiLEAN boards, issues move faster and with less friction. Escalations are clearer, ownership is visible at every level, and management discussions stay connected to what is actually happening on the shop floor. Over time, this creates stronger alignment across tiers and more consistent follow-up on performance deviations.

A practical daily management board brings KPIs and follow-up into one shared view so teams can manage performance every day.

In the example shown, the DigiLEAN board combines daily status indicators, KPI trends, and an action list. Color-coded visuals make deviations in safety, quality, cost, and delivery visible immediately, while trend charts help teams see whether issues are isolated or recurring.

The action list at the bottom links KPIs directly to follow-up, with clear ownership, deadlines, and progress. This ensures that problems identified during daily meetings lead to concrete actions rather than delayed reporting.

A layout like this supports fast reviews, focused discussions, and consistent follow-up – turning KPIs into an active part of daily management rather than static metrics.

Introducing or refining daily KPIs works best when the focus is on usability, not volume. The goal is to support daily management and decision-making, not to create additional reporting effort.

| Focus area | What this means in practice |

|---|---|

| Selecting the right KPIs | Choose KPIs that reflect your operational priorities and can be influenced on a daily basis by the teams reviewing them. |

| Keeping it simple | Avoid KPI overload. Track only KPIs that teams can understand, discuss, and act on during daily management. |

| Coaching frontline teams | Ensure teams understand what each KPI measures, why it matters, and how their daily work contributes to the result. |

| Connecting KPIs to problem-solving | Use KPI deviations to trigger improvement ideas, A3 problem-solving, or incident follow-up so issues are addressed and not forgotten. |

When these principles are applied consistently, KPIs become a practical part of daily work rather than an administrative task.

Use deviations to trigger improvement ideas, A3s, or incident reports – ensuring issues don’t get lost.

When reviewed consistently, KPIs become the engine behind daily accountability and a sustainable continuous improvement culture. Here are a few characteristics of good manufacturing KPIs below:

| Characteristic | What it means in practice |

|---|---|

| Daily accountability | KPIs are reviewed every day, ownership is clear, and deviations lead to immediate follow-up rather than delayed reporting. |

| Action-oriented | KPIs highlight where action is needed today and are directly linked to tasks, improvements, or problem-solving activities. |

| Consistently reviewed | The same KPIs are reviewed in the same way each day, creating stable routines and predictable management behavior. |

| Support continuous improvement | Trends and recurring deviations become visible over time, helping teams identify where structured improvement is required. |

| Connected across levels | Team-level KPIs feed into higher-level views, ensuring alignment between shop-floor performance and management priorities. |

| Simple and focused | Only KPIs that drive discussion and decisions are included, keeping attention on what truly matters. |

When KPIs are clearly defined, reviewed at the right tier, and connected to action, they become a practical management tool rather than a reporting exercise.

By keeping KPIs visible, focused, and consistently reviewed, organizations create stronger alignment from the shop floor to management and lay the foundation for sustainable daily management and continuous improvement.

A daily management board should typically include 5 – 7 KPIs. Best practice is to focus on a limited set of metrics that can be influenced daily. If a KPI does not trigger discussion or action during the daily meeting, it does not belong on the board.

KPIs should sit at the level where action can be taken. Team-level boards focus on KPIs operators and team leaders can influence directly, while management-level boards aggregate selected KPIs and escalated issues from multiple teams. This ensures decisions are made at the right level without overloading leadership with detail.

Manufacturing KPIs should be stable enough to create routine but reviewed regularly to stay relevant. Best practice is to reassess KPIs periodically (for example, quarterly or after major operational changes). KPIs should be adjusted when they no longer drive discussion, improvement, or learning.

Daily KPIs are those that reflect immediate operational performance, such as output, defects, downtime, or efficiency losses. Weekly or monthly KPIs are typically trend-based or financial summaries used for review and reflection. Daily boards should stay focused on what teams can act on immediately.

Standardization works best when the structure is common, but targets and ownership remain local. Best practice is to use the same KPI categories and definitions across plants while allowing teams to track line-specific performance. This enables comparison without losing local relevance.

A successful transition starts by digitizing existing boards rather than redesigning everything at once. Best practice is to replicate current daily management routines digitally first, then gradually benefit from easier updates, shared visibility, and reduced manual work – without disrupting established ways of working.

You can watch DigiLEAN boards DigiLEAN intro video to deepen your understanding of manufacturing KPIs in daily management boards, book a demo to walk through the workflow with an expert, or see digital daily management boards live by starting a free trial and exploring the platform yourself.