- Product

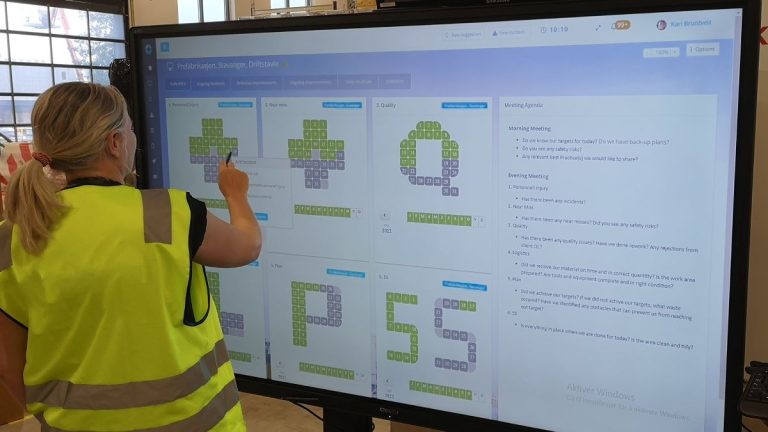

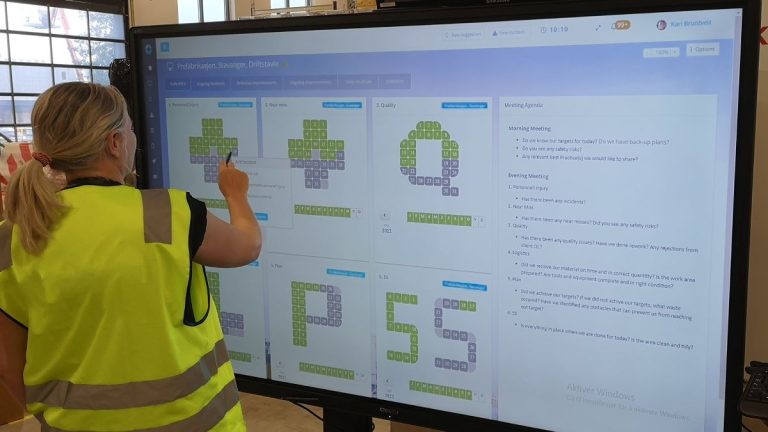

Interactive boards. Fully customizable.

Capture, prioritize and follow up improvements.

Report and manage incidents. Visualize reports and statistics.

Operationalize your strategies and integrate your whole organization.

Access your tools in Microsoft Teams.

Customized templates. Problem solving, business development etc.

Manage project individually or in portfolios with visual and interactive tools.

Create and share best practices, one-point-lectures and standards.

Easy access to tasks, improvements and incidents.

Integrate DigiLEAN with your existing IT systems.

Meeting the demand of larger organizations.

High security level by default.

In less than 4 min

- Use Cases

Interactive tools for both shop floor and administration.

Visual project management.

Maintain standards. Manage incidents and discrepancies.

Manage tasks, integrate with problem-solving and continuous improvement.

Lean daily management tailored for healthcare.

Team task management, problem-solving and visualization.Case management, improvements, problem-solving, and strategy alignment.We have a LEAN solution for you too. Just ask!

We meet the demand of larger organizations.

- Pricing

- Shop Floor

- Product

Interactive boards. Fully customizable.

Capture, prioritize and follow up improvements.

Report and manage incidents. Visualize reports and statistics.

Operationalize your strategies and integrate your whole organization.

Access your tools in Microsoft Teams.

Customized templates. Problem solving, business development etc.

Manage project individually or in portfolios with visual and interactive tools.

Create and share best practices, one-point-lectures and standards.

Easy access to tasks, improvements and incidents.

Integrate DigiLEAN with your existing IT systems.

Meeting the demand of larger organizations.

High security level by default.

In less than 4 min

- Use Cases

Interactive tools for both shop floor and administration.

Visual project management.

Maintain standards. Manage incidents and discrepancies.

Manage tasks, integrate with problem-solving and continuous improvement.

Lean daily management tailored for healthcare.

Team task management, problem-solving and visualization.Case management, improvements, problem-solving, and strategy alignment.We have a LEAN solution for you too. Just ask!

We meet the demand of larger organizations.

- Pricing

- Shop Floor

An introduction to DMAIC

DMAIC is an acronym for Define, Measure, Analyze, Improve and Control and is one of the tools of the Six Sigma philosophy.

DMAIC is used as a structured method to improve business processes. As with the Six Sigma philosophy, it is normally data driven and focused on improving a certain process as a project.

Define

– Problem

– Opportunity

– Customer demand

– Strategic activity

Establish a common understanding of the purpose and objective. Key factors to include are strategic alignment, voice of customers, and improvement potential.

Measure

To know if, and how much you improve, you have to measure. First, define your measurements and benchmark your current performance. Keep close attention to the scope at hand, so the measurements are relevant for your purpose.

Tool tips: Trend charts, pareto diagram, process map.

Analyze

Analyze areas of improvements in your current processes and identify root causes. Problems may be low quality, scrap, variation, non-productive time etc.

Part of the analysis can also be looking at your configuration, assessing your process’ capabilities and capacity. Are you able to reach your goal at all?

Tool tips: Root cause analyses, A3, cause and effect diagram, fishbone diagram, 5x why, process map, regression analysis.

Improve

Now, you know the problem, you know the underlaying reasons. Develop a solution and implement it.

Again, make sure your measurements are covering both the problem and solution to ensure comparability.

Have a plan for how the actions will give the expected results, and when you will see the results. Some changes may have immediate effect, while others take longer both to implement and to give results.

Tool tips: Project charter, plan and action lists

Control

There are two key aspects to this phase. One is to ensure you get the required results, and the second is to sustain that performance.

You have to sustain your improvements, set a new standard and built further improvements on top of it. We have all seen improvement projects that returns to old habits and poor results as soon as the project is completed.

Create an improvement sustainment plan. Involve the team in the planning, share ownership and celebrate the success helps building a culture. The plan should also have an action plan in case performance drops below a target to turn the trend back up again.

Tool tips: 5S, Statistical Process Charts, Target graphs, (quality) incident follow-up, standard work, documentation

© 2025 DigiLEAN AS