In daily manufacturing operations, many problems have a clear or easy-to-find cause. These are typically short-term, operational issues that need to be handled quickly and consistently.

3C problem-solving is a Lean method designed for exactly this purpose. It structures problem-solving into Concern, Cause, and Countermeasure, making it easier for teams to identify issues, understand why they happen, and take action.

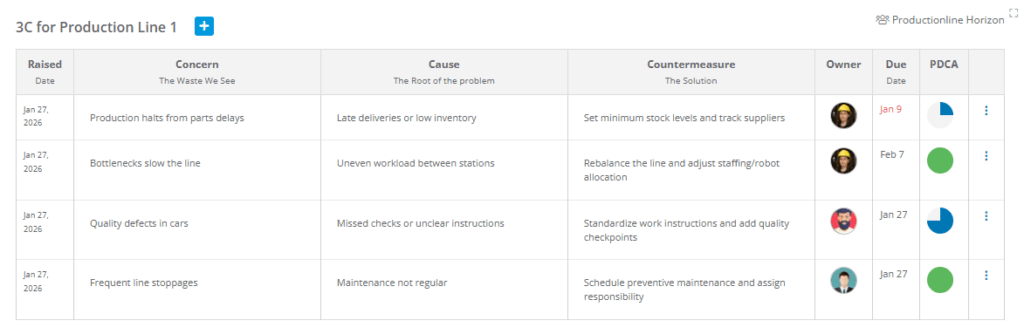

3C is widely used in Lean manufacturing, quality management, and Daily Management. When supported digitally, it becomes a powerful tool for follow-up, visibility, and learning across the organization.

This article explains:

3C stands for:

In quality and Lean environment, the 3C model provides a common structure for problem-solving. It ensures problems are clearly described, causes are discussed before actions are decided, and countermeasures are followed up.

Because the method is easy to understand, it is often used directly on the shop floor as part of Daily Management, SQCDP boards, and tiered meetings.

The Concern describes what is wrong. It should be factual and specific, without assumptions or proposed solution.

A good concern:

Example:

“Assembly Line B missed its daily output target on three consecutive shifts due to unplanned downtime.”

In Daily Management, concerns are often identified during SQCDP reviews, daily stand-ups, or shift handovers.

In DigiLEAN, concerns are typically registered directly on a digital Daily Management board. This makes them visible across shifts and ensures they are not lost or forgotten.

The Cause explains why the concern occurred. These steps are critical. If the cause is not understood, the problem is likely to return.

In 3C, cause analysis is intentionally lightweight. It often includes:

Example:

“The downtime occurred because changeovers steps were not standardized, leading to setup error between shifts.”

The goal is not deep analysis, but a shared understanding of the most likely cause that can be acted on.

In DigiLEAN, causes are linked directly to the concern and documented as part of the same workflow. This makes it clear why a specific countermeasure was chosen.

A Countermeasure is an action that directly addresses the identified caus.

Effective countermeasures:

Example:

“Create a standardized changeover checklist, train all operators, and review adherence weekly for four weeks.”

Countermeasures often lead to updates in standards work, training material, or routines.

With DigiLEAN’s built-in 3C functionality, countermeasures are tracked digitally, assigned to responsible roles, and followed up through Daily Management as a part of DigiLEAN’s continuous improvement approach. This reduces the risk of actions being agreed but never completed.

3C fits naturally into Lean daily management, it is commonly used:

When handled manually using handled whiteboards, paper, or spreadsheets, organizations often struggle with follow-up, visibility, and learning over time.

By digitalizing the 3C process, teams gain:

This is where DigiLEAN’s 3C solution supports Lean practices rather than replacing them.

| Method | Typical Use | Complexity |

|---|---|---|

| 3C | Daily operation problems | Low |

| 5 Why | Root cause exploration | Low |

| A3 | Complex or cross exploration | Medium |

| 8D | Customer complains and quality | High |

| DMAIC | Data-intensive improvement work | High |

3C is often used as the first level of problem-solving. If a problem continues or increases in impact, it may be escalated to an A3 or other method.

Manufacturing teams use 3C because it:

When combined with a digital platform like DigiLEAN, 3C becomes easier to follow up, easier to scale, and easier to learn from.

3C stands for Concern, Cause, and Countermeasure. It is a structured problem-solving method used in quality and Lean Management.

Yes. 3C is commonly used in Lean manufacturing, particularly in Daily management and SQCDP routines.

3C is suited for smaller, operational problems that require fast and structured actions. A3 is better suited for more complex or cross-functional problems.

Yes. Many organizations use digital Daily management systems to manage 3C issues, improving follow-up, visibility, and learning across teams.