Production downtime is one of the most persistent and costly challenges in manufacturing. Whether it shows up as unplanned machine stops, quality issues, or waiting for decisions, downtime directly affects output, delivery performance, and stability on the shop floor.

For production and operations leaders, downtime is a daily operational problem – not a theoretical one. For Lean and Continuous Improvement (CI) managers, it represents a visible form of waste that requires structured systems, not ad-hoc fixes.

This article explains how Lean management software helps reduce downtime in manufacturing by creating visibility, discipline, and follow-up in everyday operations.

Understanding the causes of downtime in manufacturing is the first step toward reducing it. In most plants, downtime is driven by recurring, everyday issues rather than rare catastrophic failures.

Typical root causes include:

| Cause of Downtime | Description |

|---|---|

| Equipment failures without systematic follow-up | Unplanned downtime continues when maintenance actions are reactive and learning is not standardized. Research on proactive maintenance shows that the lack of structured follow-up is a major reason for repeated stoppages. |

| Missing ownership | Problems are identified but not clearly assigned to an owner, resulting in unresolved root causes and recurring issues. |

| Poor communication between shifts | Critical information is lost during shift handovers, which is a well-known contributor to repeated production disturbances. |

| Lack of documented learning | When countermeasures and lessons learned are not captured and shared, the same problems reappear over time. |

When downtime data lives in notebooks, emails, or spreadsheets, patterns are fragmented and follow-up depends on individuals rather than a system. That’s where Lean management software like DigiLEAN bring value: they centralize issues, actions, and outcomes in one place, making recurring patterns visible and actionable.

Operational insight:

Downtime is rarely caused by a lack of effort. It is usually caused by a lack of system.

The cost of downtime in manufacturing is often underestimated because it includes more than just lost production time.

Industry research highlights the scale of the problem:

Beyond lost output, downtime drives:

Operational insight:

Small, frequent stoppages often cost more over time than rare major breakdowns – but they are harder to detect without structured tracking.

To understand how to reduce downtime in production, it is important to treat downtime as a management issue, not only a technical one.

Downtime persists when structure, visibility, and follow-up are missing. Lean daily management addresses this by creating a routine for reviewing problems, assigning ownership, and verifying countermeasures.

Research on Lean implementations consistently shows that structured daily management improves operational stability and productivity.

In practice, Lean daily management enables teams to:

This discipline is a key factor in how to reduce downtime in manufacturing sustainably.

Lean management software strengthens this daily discipline by making downtime and improvement activities visible in real-time and ensuring consistent follow-up.

Here’s how DigiLEAN supports how to reduce downtime and increase productivity:

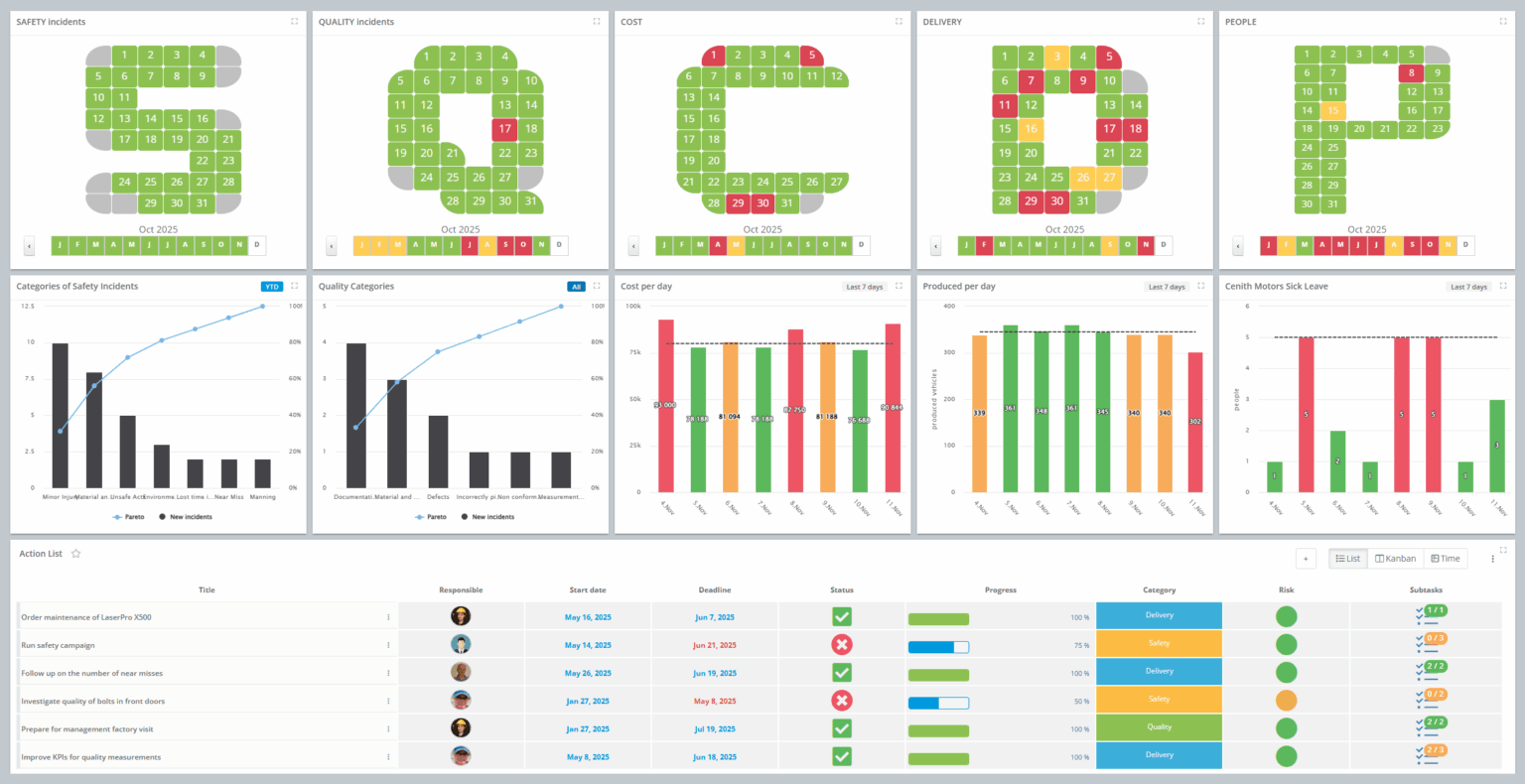

With interactive boards and dashboards, teams record issues, KPIs, and deviations consistently. This replaces scattered manual boards and Excel trackers with a central source of truth.

Each issue or improvement comes with a clear owner, priority, timeline, and status. This ensures problems are not forgotten and actions are measured to completion.

Structured problem solving through digital A3 templates that help teams analyze recurring downtime using a standardized Lean method. By linking problems, actions, and follow-up in one system, root causes are documented and learning is preserved to prevent the same downtime from recurring.

Production, maintenance, and management teams share access to the same data. This improves decision-making and helps eliminate delays that stem from disjointed communication.

In the real world, one manufacturing company – Marquardt – implemented DigiLEAN across 10 locations on 5 continents in just two months. They standardized digital boards that unify KPI tracking, deviation histories, and standardized follow-up globally.

Since implementing DigiLEAN, Marquardt has:

For operations leaders, this translates directly into fewer repeated stoppages, faster decision cycles, and more predictable workflows.

Completely eliminating downtime in manufacturing does not happen overnight. It happens through systematic learning.

Daily Lean management makes it possible to:

Lean management software supports this process by preserving learning over time, ensuring that improvements are not lost when people or shifts change.

Production downtime is best addressed through daily, structured management – not one-off fixes.

One-time solutions do not scale. Systems do.

Lean management software like DigiLEAN supports a systematic approach to reducing downtime in manufacturing by:

Many manufacturers struggle to track downtime consistently because data is scattered across shift logs, whiteboards, and spreadsheets. Lean management software like DigiLEAN helps reduce downtime in manufacturing by standardizing how stoppages are logged and reviewed, creating a single source of truth across shifts and teams.

Small stops often go unnoticed but add up quickly through lost flow, repeated disruptions, and recovery time. This hidden impact significantly increases the cost of downtime in manufacturing, often more than rare major breakdowns.

Yes. Many downtime issues are caused by missing ownership, poor follow-up, and communication gaps rather than machine limitations. Addressing these gaps is a practical way to reduce downtime in production without major capital investments.

Completely eliminating downtime in manufacturing is a long-term direction rather than an immediate goal. However, organizations that use Daily Management and Lean management software can systematically reduce recurring downtime and prevent the same issues from returning.

You can watch DigiLEAN intro video to deepen your understanding how Lean management software helps to reduce downtime, book a demo to walk through the workflow with an expert, or explore DigiLEAN by starting a free trial and experiencing the platform yourself.