LEAN, Six Sigma, Kaizen, TQM, TPM have proven their effectiveness for decades. Based on production companies, reducing waste and increasing production performance, the LEAN work has traditionally been performed on physical whiteboards. Now is the time to digitize LEAN!

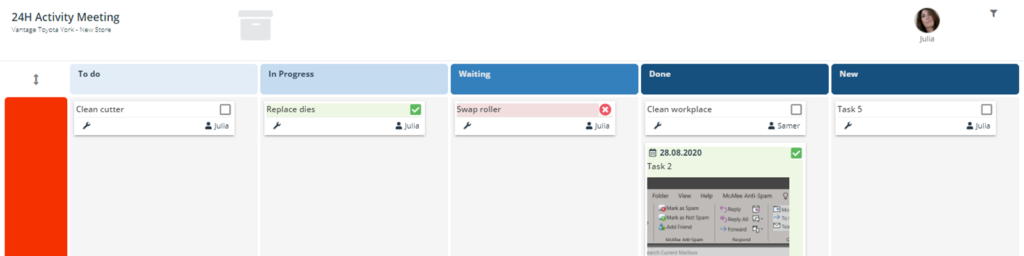

Teams gather in meetings in front of the boards to discuss problems and challenges in the operations, the latest KPI’s are presented, tasks and responsibilities are assigned to team members.

Yes, this is the first phase of what’s called “Visual Management”. The team- and organization activitites are visualized on the boards. Every day or every week, depending on the meeting type and intervals, the meeting leader has to update the KPIs, extract data and reports to update statistics, print graphs and charts to put up on the board. This is very time consuming, repeating work with a huge potential for inaccuracy.

DigiLEAN’s interactive always-updated boards help us stay ahead at all times.

When you are presented with a lot of information in a short period, a lot of details is filtered out due to our brains lack of short term memory capacity (or lack of memory practice). We group and categorize information with the result of generalizing it – details are lost.

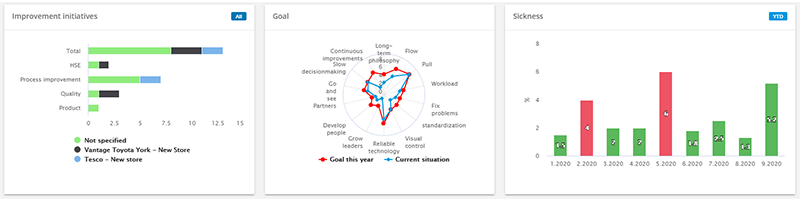

First of all, using digital LEAN boards, such as DigiLEAN, you don’t have to run reports, extract data to update your board. DigiLEAN is a live system constantly being fed with the latest updates on activities, KPI’s, fed directly through the tools, automatically generated or pulled from integrated third party systems.

With DigiLEAN, the users can also bring with them their tasks, add and follow up incidents and improvements where ever they go using the mobile app. This way, the follow-up items are always available and adding an improvement suggestion or an incident report is easier than ever!

Easy-to-use board designer lets you create your own dashboards. Add visualization apps, add data to present, place and scale and make beautiful dashboards in minutes. The dashboard can consist of both presentation apps and interactive apps for active use in team meetings, follow up’s etc. Visualize you team activitiy boards, time boards, project overviews, action lists etc.

Different boards for different purposes. Customize your boards to fit your requirements. Use the boards actively in your team meetings – it is optimized for touch. Put it on a large touch screen, and replace your traditional whiteboards.

All the team input is automatically saved. Adding responsibles with active follow up either through personal boards or the mobile app ensures actions are not forgotten or slipping. It increases the ownership of the responsibility and team transparency. And with more transparency, you also have the foundation to improve team communication and collaboration.

LEAN isn’t only about the boards. As such, DigiLEAN has a lot more to offer. Including Kaizen (Continuous Improvement), incidents (learning), A3 method and project management enable companies to work holllistically with LEAN . In DigiLEAN all these modules integrates with each other and boost the improvement possibilities.

Are you still wondering why you should digitize LEAN?

Let’s discuss it.